ttuser

-

Posts

17 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Blogs

Posts posted by ttuser

-

-

^ that one looks soooo badass! any more photos, ttuser?

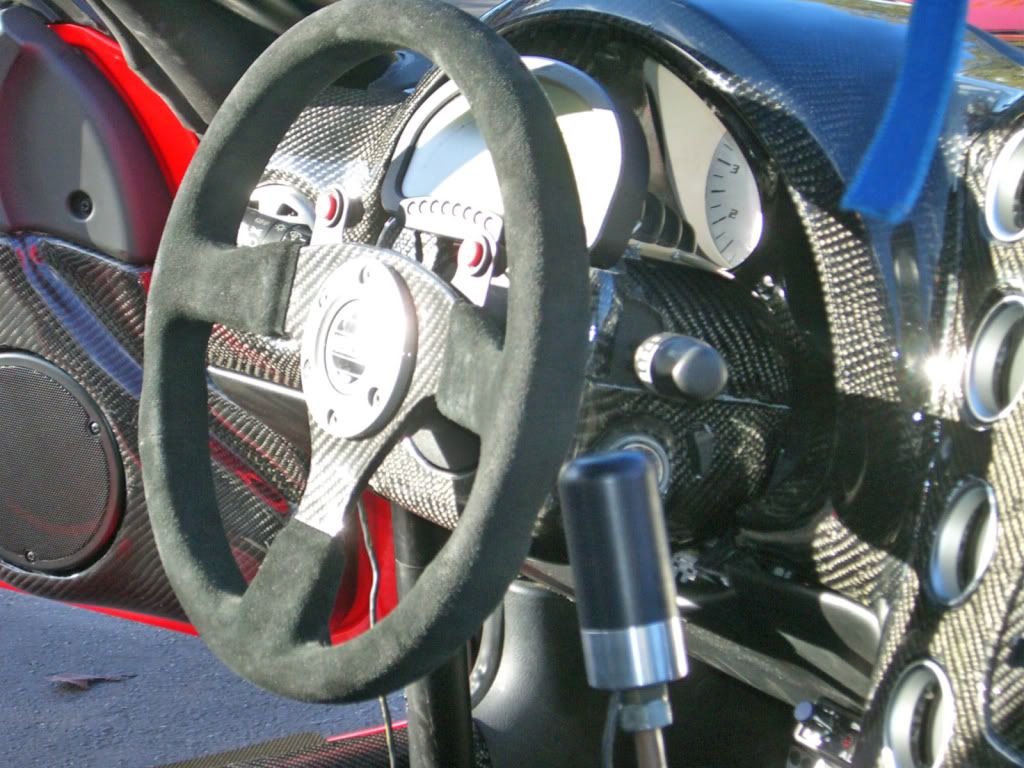

here's a few more pictures, including some interior shots

-

The H1 Alpha is my daily driver. I take it to NYC, Philly, all around, never a problem. I love it!! I bought it new in 2006 and have 80k miles on it. The only way I replace it is with another. When the advert said, "Like Nothing Else" that was 100% spot on. Any questions, feel free to ask, but all you will hear from me is praise. Of all of my automobiles, Lambo, Ferrari, Cayenne Turbo S, RR, Bentley, C63 (wife's car), etc. The Hummer H1 Alpha is the only one I could not live without. Nothing else comes close for me. But, I grew up hard core military, going to Military school from 6th grade on, service, etc.

My H1 alpha is my DD as well. It too is my favorite DD of all time, like nothing else.

-

Just curious, if you are laying carbon on something and mess up, can you sand it down and start over or is the piece you are laying the carbon on toast?

if you let the resin fully set, in most cases you can peel the overlay off. I rewrapped many a piece while during my learning curve

-

Very nice work! I didn't vacuum bag my parts. Door panels certainly didn't need it since they were relatively flat, console could have gone either way, but the radio bezel really should have been. Next parts I do will certainly be under vacuum so I can understand both methods.

Specially, my question was how did you lay up two pieces without them fraying along the edge? My parts were all single pieces of fabric and I covered the parts with several inches left past the part edge and trimmed after it resin application. How did you trim the CF fabric, lay it on the part with the edge in a visible area, and NOT have it fray and ruin the weave? That is very impressive and something I don't get understand with lamination.

The way I had imagined it was to trim the fabric after the first top coat was 90% cured so that it could still be trimmed with an exacto knife without hurting the weave, but I really don't think that would work right.

i made cuts with long shears, i got them from a website, they are for cutting carbon weave & other stuff. I also used a radial cutter (think thats the name) its a round blade that rolls along and cuts. I'd generally cut a pattern, put resin on the piece and let is set, then carefully lay teh weave on it. I'd keep the seam to a curve, corner or edge so they were as noticeable to the eye. change gloves before you lay the weave so there is no resin to cause the weave to stick to the gloves, causing fraying

-

ttuser - question for you. Are this pics work that you did or from another site? The edge that follows the top of the center dash piece and curves down towards the console, how did you do that and keep a good weave at the ends of the two parts of CF? I have some ideas about how I would attempt that but haven't tried it yet.

that's my car, my work. I vacuum bagged the parts, it was how i felt comfortable doing the work. I know it can be done without bagging, but thats how i did mine

frank

-

for those that want to learn, racingcomposites.net is a really good site.

like the OP said, the theory is simple, it'll take awhile to learn the techinque.

i bought duplicate parts that i wanted to overlay so my car wouldn't be down while I went through the learning curve.

aircraft spruce is a site where i bought a good amount of the materials. when you buy the cf weave make sure you get the 2x2 twill.

If you attempt, don't be discouraged. I wrapped & rewrapped a few pieces until i got it right.

BTW, OP's parts looks as good as some of the pro done stuff i've seen out there!!!

here are a few pics of results

-

Better?

i'd take her to cancun. That little dog has the right idea on licking her, lol

-

for the guy who asked about the differences in the alpha, from wikipedia:

The "Alpha" was an extensively re-engineered H1 that was equipped with GM's Duramax Diesel and 5-speed Allison transmission. The previous version of the H1 with the 6.5L "Optimizer" turbo-diesel engine suffered from sluggish sales; lack of power was one of the reasons for customer resistance. In 2002, AM General CEO Jim Armour took the idea of repowering the H1 to Bob Lutz and the GM Luxury Vehicle committee. GM soon approved the use of their Duramax/Allison powertrain for the H1. This would support the continuation of the H1 as the grandparent of the Hummer portfolio; it would also allow AM General to give the truck a much needed dose of updating in terms of power, torque, refinement and the ability to meet 2004 heavy duty EPA emissions requirements.

The update program commenced in late 2002 with production launch slated to be fall of 2004. The engineering team chose the engine variant out of the GMT560 truck (the C4500) because it packaged better into the H1 engine bay; however, 23 engine component changes were required and the team had to do a 2.0 in (51 mm) body lift to accommodate the taller engine and its turbo housing (a prior 0.5 in (13 mm) lift had been done for MY96 to accommodate the turbo on the 6.5L engine). The GMT560 engine calibration was used with minimal modification; engine output was 300 hp (220 kW) and 520 lb·ft (705 N·m) of torque. Due to the Duramax engine being equipped with cooled exhaust gas recirculation and an internal engine oil cooler, the team had to deal with a 40 percent heat rejection increase to engine coolant. However, they were unable to increase the size of the cooling pack between the air-lift brackets that protrude from the hood. This meant dramatically re-engineering the fan system by putting the fan directly under the coolpack and driving it through a special gearbox directly off the crankshaft damper pulley. Several other cooling system modifications were required to assist with cold starting from −30 °F (−34 °C).

Other major modifications included the use of special high-strength steel in the chassis frame, a more powerful steering gear; quieter axle differentials, redesign of the geared hubs to use quieter helical gears, new induction, exhaust and electrical power systems; and re-engineering of the fuel supply and filtration system.

Off road the much higher torque of the engine, combined with a lower gearing ratio (about 44.5 to 1 in low lock), made the truck much more powerful. The Duramax engine delivered more torque at lower engine speeds than the 6.5L, so the team actually had to calibrate the torque management to protect certain driveline parts. This new torque profile coupled with centralized tire inflation and AM General's new interior resulted in the complete re-engineering of everything except the carryover body made of aluminum beams and panels.

Production launch was early in 2005, and continued until production ceased in mid-2006. All vehicles built during this time are classified as model year 2006 (10th digit in VIN is a 6.)

The program was cancelled May 12, 2006 because GM decided to withdraw technical and financial support for future engineering and recertification.

-

Friggin sick! Maintainence costs are high though?

with older models, i think yes. with the '06 's (duramax engine, allison transmission) not too bad

-

Very Nice... what headlights are they?

And are the strip LED lights a good option?

the headlights are starr hid's

the LED is very useful if your offroad in the dark. I flash it on my back yard and it looks like daylight, lol

-

here's a few pics of my '06 alpha

-

ablowtorch a hammer and and axe and 1/2 hour so and i would fix that guy right up

-

saw this car in person in a C&C we had in our neighborhood, it is sweet!!!

-

I'm agree with everything you've said except for the first part. Why do you say that Miami couldn't hold the event? The facility is just that, a facility. It is the organizing body that will determine how the event is run, timed, scored, etc. There's no reason why the Texas Mile people couldn't hold a stellar event at Miami. I believe that the short stopping distance at Goliad was the largest contributor to that crash.

I think the answer to short dtopping distance in Goliad is both yes and no (as far as being a contributor to the crash). The yes part is i believe Richard was intending to pull the chute b/c of his 250 runs last yr, he felt he was running out of braking room, car spinning as a result.

The no part is he didn't "need" to pull chute on this run @ 235, so the question is what caused teh spin, then wreck. lastly, the berm, curb or whatever it was more than likely caused the car to get airborne, sans that he most likely would spun and been done.

I can't offer an opinion for all the miami events, but the exotics rally one in may of this year (or april, i dont' remeber) was poorly run, I wouldn't travel across the coutry to go to an event put on by them again.

-

so contrary to what was posted on the other thread, I saw chute deployed then brakes applied, no?

Texas invitational Thread (April 10th-12th) 2015

in Archived Content

Posted

Aaron and the Nth crew are far from amateurs, they've done some work on my car and are extremely professional and very knowledgeable, aside from being super solid guys. That blue viper won the RWD class TI and went to the KOTS finals and lost to ASS last TI, so yea they been working on that car" for like ever", Successfully!!!! nobodies name is coming off the side of that trailer, silly rumour mongering